| << back to overview | |||||||||||||||||||||||||||||||||||||||

| Save energy and costs through effective measurement data acquisition |

|||||||||||||||||||||||||||||||||||||||

| A way to save costs and protect the environment | |||||||||||||||||||||||||||||||||||||||

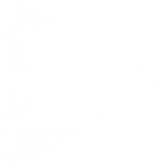

| Reducing energy costs is a good way for many companies to save money. Energy consumption varies from industry to industry, and every company has its own specific energy guzzlers. Nevertheless, there are certain areas that cause high energy requirements in most companies. Processes that generate heat or cold, such as heating or air conditioning, are particularly energy-intensive. Devices that are in continuous operation, such as pump systems or ventilation systems, also contribute significantly to energy consumption. Although lighting, computers, routers and other electrical devices also require electricity, these generally only account for a small proportion of the total costs. Savings in these areas can also often be made quickly, which has a positive impact in the short term. This chart shows the average savings potential in selected areas: |

|||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||

| Production environments are usually more complex | |||||||||||||||||||||||||||||||||||||||

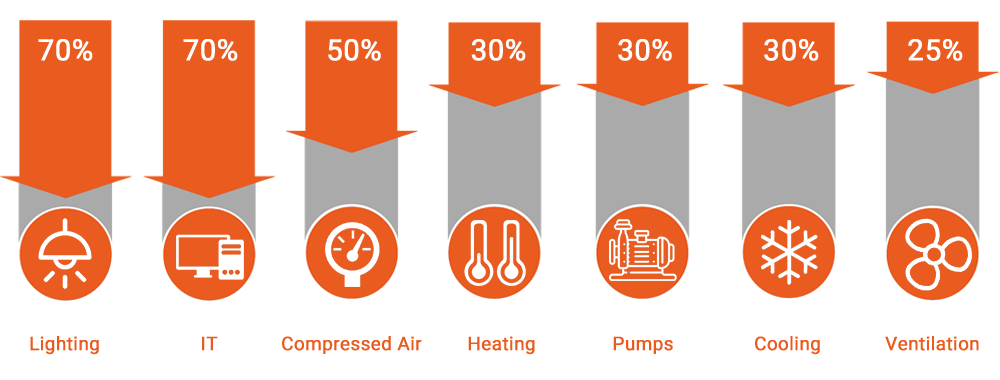

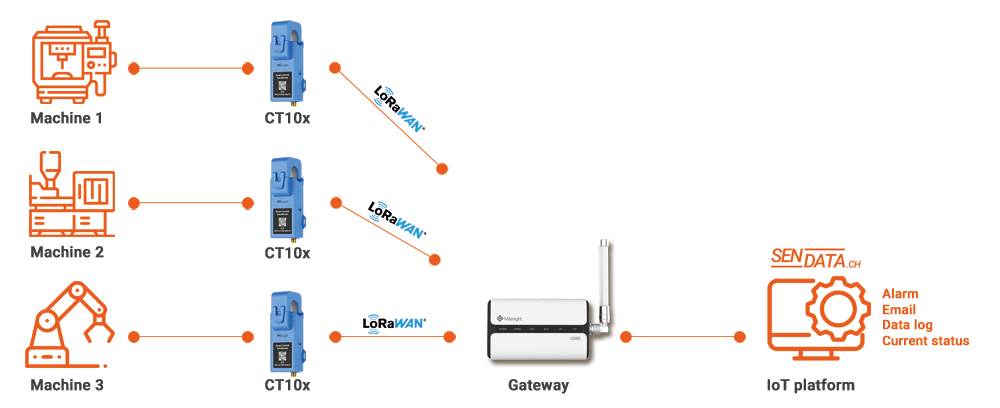

| There is also potential for savings in production facilities and machinery, but this is usually not as quick and easy to implement as with lighting and IT. The first step is to identify which systems consume how much energy. As the machines and systems are not always all in the same place and are also from different manufacturers, it is easiest to collect the measurement data wirelessly when the system is fed in. Sometimes, however, it is also necessary to record the data at different points in the overall system in order to record the energy consumption of individual sub-areas. This is where our non-invasive and battery-free system comes into play. The Sensor is simply clicked over a phase and draws its energy from the induction. It is now ready to send the measurement data wireless to our gateway. |

|||||||||||||||||||||||||||||||||||||||

| This is what a typical measurement data setup from us looks like: | |||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||

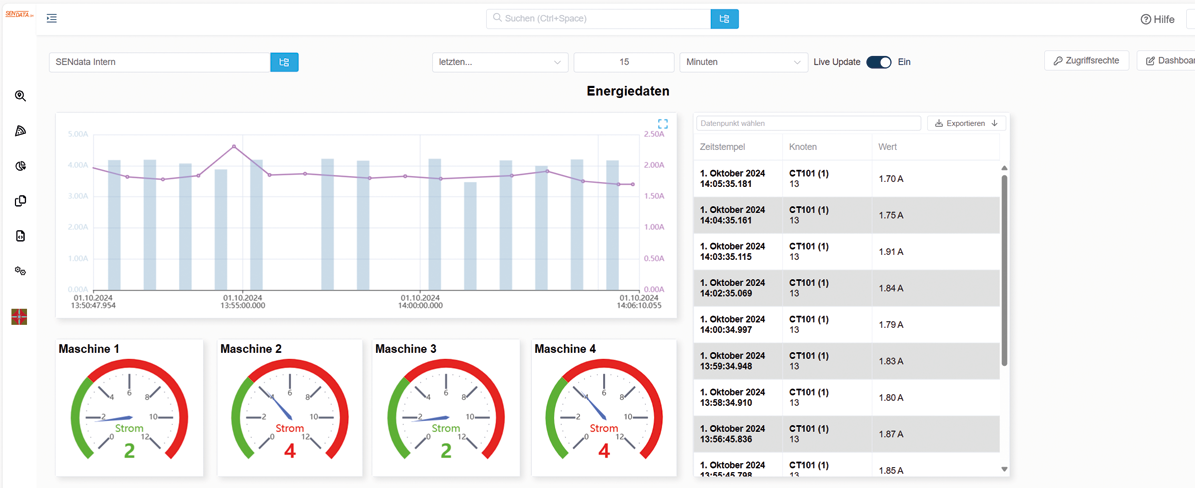

| And this is what your overview of the data looks like, for example: | |||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||

| The information obtained can now be used to initiate optimization measures. Once completed, these savings will be clearly visible in the energy data records. In addition to the financial benefits, recording measurement data also offers the opportunity to raise awareness of one's own energy consumption. By visualizing and understanding their energy consumption, consumers and companies can make more conscious decisions and further optimize their consumption. Overall, the systematic collection of metering data is a crucial step towards a sustainable energy future. Let's go for it! |

|||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||

| Some highlights of the system | |||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||

| Simple solutions are often the best solutions. This is about food for thought, ideas and possibilities. Our technicians are happy to discuss your concerns via LiveCall, chat, email or telephone. The basic ideas shown here can be rebuilt or extended according to your needs! |

|||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||

| Content: #Current sensor #Current data logger #Current data acquisition system #Energy monitoring #Measured data acquisition #Real-time monitoring of electricity #Load profile analysis of electricity #Digitalization of electricity data #Sensor technology for electricity measurement #Energy management #Network monitoring #Automatic measured value transmission #Current consumption data acquisition #Data visualization for electricity consumption #Energy data acquisition #Collect machine data #Record machine data |

|||||||||||||||||||||||||||||||||||||||