| << back to overview | ||||||||||||||||||||||||||||

| Solution approaches from the area of level monitoring | ||||||||||||||||||||||||||||

| Specific adjustments directly on the product Often you don't have time to quickly calculate in your head how much fill quantity the tank still has when the display shows 7.67 mA from the sensor. Sometimes the exact number of liters is not relevant, it is more a question of whether the tank is half or 2/3 full, or how quickly the filling quantity decreases or increases. Exactly for these applications there are process meters and bar graphs. The process meters convert the analog value from the sensor directly into liters or percent, for example. This gives you, the user, a clear value. The bar graphs, on the other hand, are used more for detecting trends. The single or multi-colored bar graphs give a good quick impression of the filling quantity and you can recognize a tendency. The use of ultrasonic sensors is clearly preferred for such applications because they are not influenced by color, shape and aggregate state (solid, liquid, powder, pasty...) of the content to be measured. |

||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||

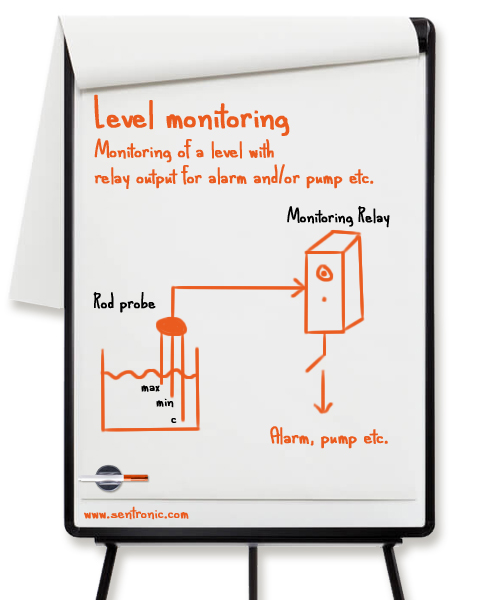

| A simple and robust level monitoring system Level monitoring relays are a simple way to monitor the level of conductive liquids. The relay requires three points in the tank or well. "c" is the common contact, this is placed as far down in the tank as possible. In addition, there are "min" and "max", which are placed at the appropriate points in the tank. This probe can be a rod probe to saw off yourself, but also simply three wires or chains. In principle, all conductive materials will work. As soon as the level between, for example, "c" and "max" makes contact, the output of the relay switches. This can trigger a pump or an alarm, depending on what is needed. |

||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||

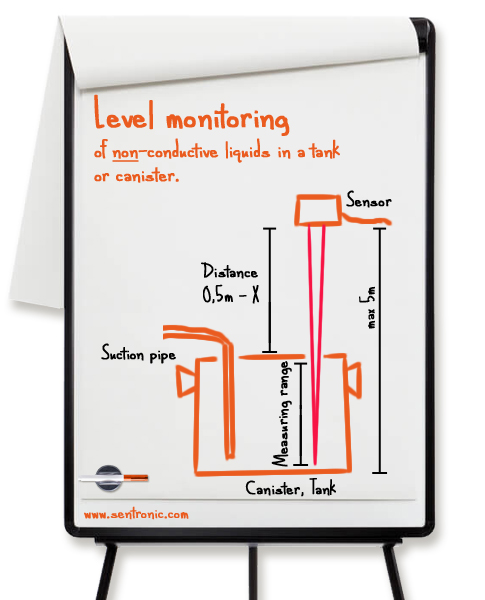

| Capture non-conductive liquids in tanks or canisters In the case of non-conductive liquids such as soap, classic solutions such as capacitive sensors or level relays are not applicable, as these require a certain conductivity. This is where measuring laser sensors come into play. They are able to reliably detect the level through small openings in the tank or canister. With an appropriate Ex laser sensor, this solution also works in an explosive environment. |

||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||

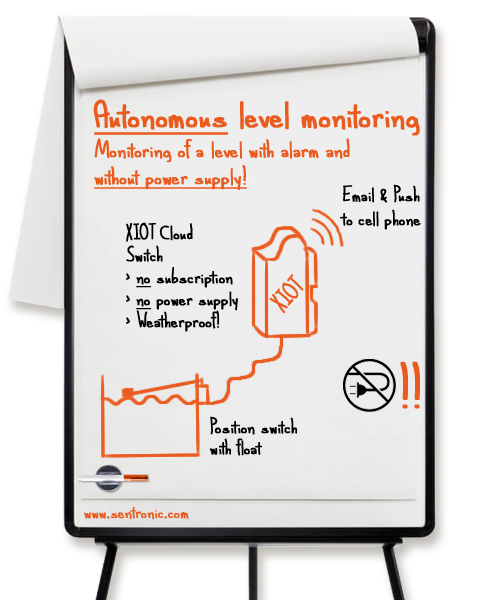

| Autonomous monitoring of levels and water levels In remote locations, monitoring a level or condition is difficult. On the one hand, there is no power supply on site, on the other hand, the conditions are usually rough and unprotected. A robust, weatherproof and, above all, power-independent solution comes into play here. The XIOT cloud switch in combination with a float switch or a position switch meets these requirements. The robust and weatherproof cloud switch reliably transmits two signals without an additional power supply to a platform, which communicates the change in switching states via email and push message. The XIOT switch is an out-of-the-box device that uses LPWAN technology. A 5 year subscription to the web platform is included in the price. Through our advanced Machine Advisor platform, the management of a very large number of cloud switches is also clearly possible. |

||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

| Simple solutions are often the best solutions. This is about food for thought, ideas and possibilities. Our technicians are happy to discuss your concerns via LiveCall, chat, email or telephone. The basic ideas shown here can be rebuilt or extended according to your needs! |

||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||

| Content: #Regulate filling level #Measure filling level #Display filling level #Filling level liters #Filling level percent #Monitor filling level #Regulate level #Measure level #Display level #Monitor level #Level control #Level monitoring #Level display #Level control #Level display #Level display #Level relay #Level monitor #Level measurement |

||||||||||||||||||||||||||||

In remote locations, monitoring a level or condition is difficult. On the one hand, there is no power supply on site, on the other hand, the conditions are usually rough and unprotected. A robust, weatherproof and, above all, power-independent solution comes into play here.

The XIOT cloud switch in combination with a float switch or a position switch meets these requirements. The robust and weatherproof cloud switch reliably transmits two signals without an additional power supply to a platform, which communicates the change in switching states via email and push message. The XIOT switch is an out-of-the-box device that uses LPWAN technology. A 5 year subscription to the web platform is included in the price.

Through our advanced Machine Advisor platform, the management of a very large number of cloud switches is also clearly possible.